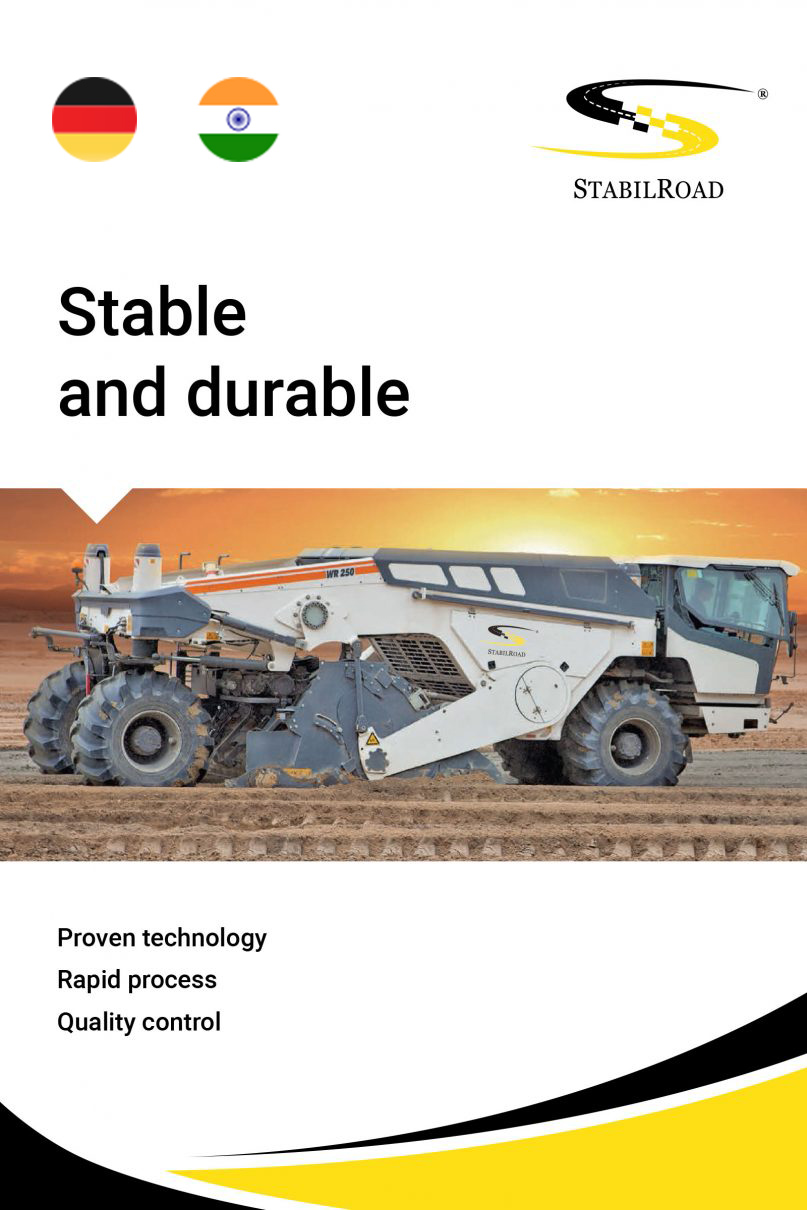

StabilRoad® is stable and durable! S

Modern civil engineering has used cement as the main stabilizer due to its excellent bonding properties. But it does not work on clay, sandy, muddy soil. In this case, besides better bonding, fill surfaces should be used. Only problem is cement-treated soils become very rigid and the risk of cracking is very high. By using the StabilRoad® cement additive in a corresponding amount with the amount of cement, there is a no significant risk of cracking. This is due to its ability to change the parameters of the concrete’s bending strength. StabilRoad® is today one of the most advanced and technologically most innovative soil stabilization material and technology in the world. StabilRoad® is a whitish powder made of 100% natural minerals with no synthetic chemicals. StabilRoad® technology has been developed in Germany and has been used for nearly 20 years in nearly all of the world’s climate zones.

Technological specifications

The most important feature of this technology is that by using the StabilRoad® additive and special technology we can significantly accelerate the construction process, reduce the cost of work, and at the same time achieve a very strong, elastic, waterproof and frost-proof surface. All this can be achieved by reusing local soil.

The biggest advantage of using such a stabilization method is that there is no need for the excavation of old or existing soil, the disposal and the return of the new ground. Some hours after the necessary work is completed can be done, the treated surface can be put into operation. Stabilizing with StabilRoad® technology entails the mixing together of existing soil (including old asphalt), StabilRoad® and cement (Portland cement needed, clinker content> 95%) is mixed together.

The StabilRoad® additive increases the process of cement hydration, in which cement particles form a reactive water by reacting new bonded compounds, which consists of a concrete skeleton. As a result of crystallisation, water-insoluble compounds are formed which make the treated layer non-water-absorbing. Increasing the cement hydration will reduce the amount of cracks caused by volume reduction, increasing the elasticity of the stabilized surface, compression and tensile strength, and the material becomes cold and waterproof.

The stabilized surface can be compared with concrete in its properties. Stabilizing with StabilRoad® is used instead of substrata and frost protection layers. By using StabilRoad®, each treated layer can also work as the top layer of the coating on low-traffic roads. Depending on the field of application, a protective layer of asphalt may be necessary as a final layer, for example by coating or asphalting.

StabilRoad® technology was first used in India in August, 2017 by M/S Krishnapatnam Port Company Limited. StabilRoad® India have done close to 6 kilometers in krishnapatnam port and close to 5 kilometers in the city of Hyderabad, close to 3 kilometers in Vijayawada in Andhra Pradesh and 6 Kilometers in Kerala with excellent results. Presently, we are also in the process of constructing roads in Andhra Pradesh, Kerala, Maharashtra and Punjab using this technology.

Consists of only 6 stages

Is scientifically proven

Meets the required conditions

Saves time and costs

Gives ecological preference

StabilRoad® is a modern and innovative soil stabilizing technology. The existing soils are processed with cement and special additive. This makes the soil very resistance to the compressive strength as well as elastic, waterproof and frost resistant.

High quality

The quality and warranty of StabilRoad® with over 20 years of experience on several continents, different climate zones and numerous soils of different types helps in great quality of construction of roads.

Economical

Stabilizing is carried out on the layers of the existing soils, by mixing it with cement and StabilRoad® additive. On the contrary to the common road construction technology there is no need to dig out existing soil. We can utilise the existing soil or asphalt. We need not bring in new soils or aggregates to construct roads.